Why Outsource?

You can’t do everything!

Well, I guess you can try but can you do them all well at the same time? One of the biggest hurdles businesses encounters is management attempting to do everything alone. Handling all facets of the business can lead to burnout and increased stress levels for management potentially affecting their health and business performance. To be most successful, owners need to focus on their core competencies. So, ask yourself: what do you do best?

Handling every task can divert your attention from what you do best. Just imagine how much better your company would function if you chose to outsource the areas for which your company lacks the resources to handle. One of these areas that is frequently lacking expertise and resources is environmental health and safety.

We offer a six-figure safety team for your company at a fraction of the cost.

As budgets continue to be tight for American companies, Hellman & Associates offers their client partners an option to create a safe environment for their employees at a fraction of the cost of hiring a full-time department.

Companies outsource various operation aspects as it can offer benefits. Here are some common reasons why businesses choose to outsource EH&S needs:

- Cost Savings: Outsourcing EH&S tasks can be more cost-effective than hiring in-house staff. Hellman & Associates offers a way to save money on salaries, benefits, office space and equipment.

- Focus on Core Activities: Outsourcing safety tasks allows companies to concentrate on core competencies and strategic goals. This way, a company can redirect resources towards growing their business.

- Access to Specialized Skills: Outsourcing your EH&S needs provides expertise without the need for expensive recruitment.

- Scalability: Companies can scale their needs up or down without the burden of adding or laying off employees.

- Risk Mitigation: Compliance matters carry legal and financial risks if not handled properly. Outsourcing EH&S responsibilities helps mitigate potential risks and ensures compliance with regulations.

Finally, while outsourcing can offer significant advantages, it’s important to choose partners carefully, establish clear communication and manage the relationship effectively to ensure the best results. H&A offers these qualities and outsourced EHS compliance management services that protect your workforce and keep your company current with regulatory requirements.

Let Hellman & Associates help you be successful.

In summary, small businesses cannot do everything on their own. Recognizing this limitation is essential for success. The strategy of outsourcing EHS tasks can add to effectively manage your company, make the most of your resources and add to your long-term growth and sustainability.

The dusts which are most often associated with workplace issues are:

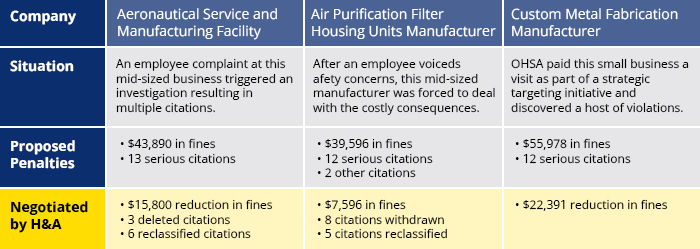

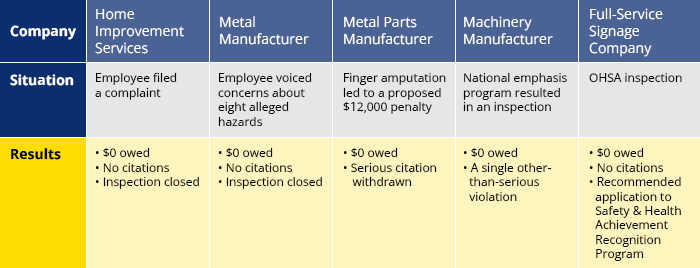

The dusts which are most often associated with workplace issues are: Hellman & Associates has seen a surge in OSHA regulatory engagement with companies during the past year. When it comes to compliance, Hellman & Associates can be the key to favorable results when facing potential violations. Hellman & Associates helps minimize financial losses when in-house compliance programs come up short.

Hellman & Associates has seen a surge in OSHA regulatory engagement with companies during the past year. When it comes to compliance, Hellman & Associates can be the key to favorable results when facing potential violations. Hellman & Associates helps minimize financial losses when in-house compliance programs come up short.

Download the poster >>

Download the poster >>

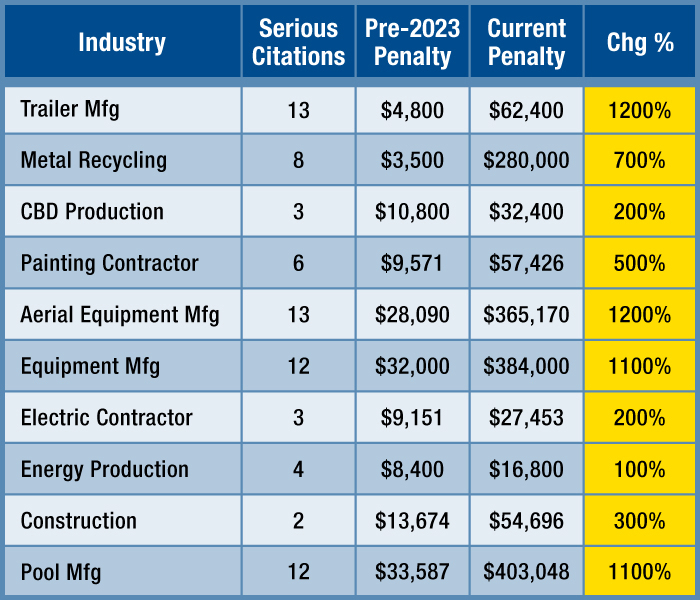

Effective March 27, 2023, OSHA will administer penalties on an “instance-by-instance” (IBI) basis for gravely serious violations. Detailed information can be found in the official OSHA memo by

Effective March 27, 2023, OSHA will administer penalties on an “instance-by-instance” (IBI) basis for gravely serious violations. Detailed information can be found in the official OSHA memo by

The summary must include the total number of 2022 job-related injuries and illnesses that were logged on your OSHA 300 form. If your company had no recordable injuries or illnesses in 2022, you must still post the form with zeros on the total line. All summaries must be certified by a company executive and remain displayed in a common area between February 1 and April 30, 2023.

The summary must include the total number of 2022 job-related injuries and illnesses that were logged on your OSHA 300 form. If your company had no recordable injuries or illnesses in 2022, you must still post the form with zeros on the total line. All summaries must be certified by a company executive and remain displayed in a common area between February 1 and April 30, 2023.